General notes on safety

Safety instructions serve the purpose of occupational safety and accident prevention. They must be observed. In order to protect you and your colleagues from damage, your cooperation is also necessary. You should therefore always work with caution and be aware that dangers are usually not obvious.

In order to ensure safe operation, the operator must ensure that the persons working on or with the device have been informed of the possible dangers of laser radiation. The accident prevention regulations and the associated manual must be made accessible at a suitable location (BGV A1, Chapter 2, § 12).

The command and warning symbols that apply and are used for the application of the respective manual are based on the statutory safety and health protection labelling at the workplace, BGV A 8:

Read and understand

Read and understand

Please observe these operating instructions!

Eye Safety

Wear laser safety goggles when the laser beam is switched on!

Unplug the projector before opening it!

Unplug the projector before opening it!

Before working on active parts of electrical systems and equipment, the voltage-free state must be established and ensured for the duration of the work!

Attention!

Attention!

Electrostatically sensitive components! Pay attention to grounding! Avoid friction!

Look out!

Look out!

General danger notice!

Warning!

Warning!

Dangerous electrical voltage!

Attention! Laser beam!

Attention! Laser beam!

Do not look into the beam or look directly with optical instruments!

Look out! Danger of falling!

Look out! Danger of falling!

For all electrical and mechanical work, sufficient stability and secure hold must be ensured.

Safety instructions for electronics

The following safety instructions are based on the statutory accident prevention regulations for electrical systems and equipment.

According to BGV A3, § 3, the entrepreneur must ensure that “electrical systems and equipment are only installed, modified and maintained by a qualified electrician or under the direction and supervision of a qualified electrician in accordance with the electrical engineering regulations”. (DIN VDE 0105)

The contractor must also ensure that the electrical systems and equipment are operated in accordance with the electrotechnical regulations.

According to BGV A3, § 6, work must not be carried out on live active parts of electrical systems and equipment.

It states: “Before starting work on active parts of electrical systems and equipment, the voltage-free state must be established and ensured for the duration of the work. The operator may only commission persons who are “technically suitable” for work on live active parts. (DIN VDE 0105)

In the event of faults in the electrical power supply, the device must be switched off immediately.

The laser projector contains highly sensitive components that are electrostatically sensitive. Do not attempt to repair the projector yourself. Take measures against static discharges and electric fields according to DIN EN 61340 – 5 -1 or VDE 0300 – 5 – 1.

Safety instructions for lasers

If the laser beam from class 2 or higher laser equipment is directed at work or traffic areas, the employer must ensure that the laser area is clearly identifiable and permanently marked in accordance with the statutory provisions.

No mirrors should be installed in the area of the laser beam to exclude dangerous reflections. Avoid direct eye contact and never look into the laser beam with optical instruments! Close your eyes and turn away immediately if the laser beam hits your eyes.

Check which laser class your device is assigned to. The laser class can be found on the nameplate on your device.

Laser Class 1

The accessible laser radiation is harmless under foreseeable conditions.

The foreseeable conditions are met during normal operation.

The limit value of the accessible radiation according to DIN EN 60825-1:2001-11 in the wavelength range from 400 nm to 1400 nm for the classification of a laser is the same between 100 s and 30000 s. The maximum permissible radiation is between 100 s and 30000 s. The maximum permissible radiation is between 100 s and 30000 s.

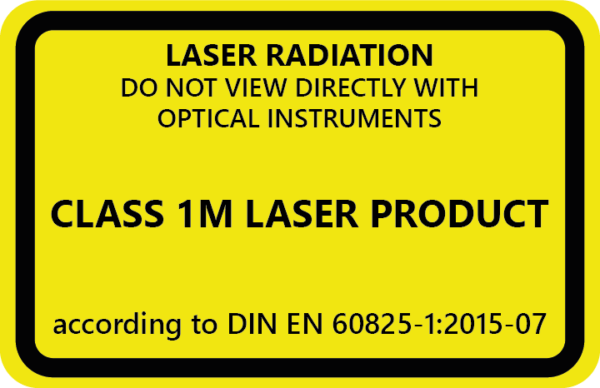

Laser Class 1M

The accessible laser radiation lies in the wavelength range from 302.5 nm to 4 000 nm. The accessible laser radiation is harmless to the eye as long as the cross-section is not reduced by optical instruments (magnifying glasses, lenses, telescopes)!

Unless optically collecting instruments are used to reduce the beam cross section, Class 1M laser devices present a comparable hazard to Class 1 laser devices.

When optically collecting instruments are used, hazards comparable to those of Class 3R or 3B may occur.

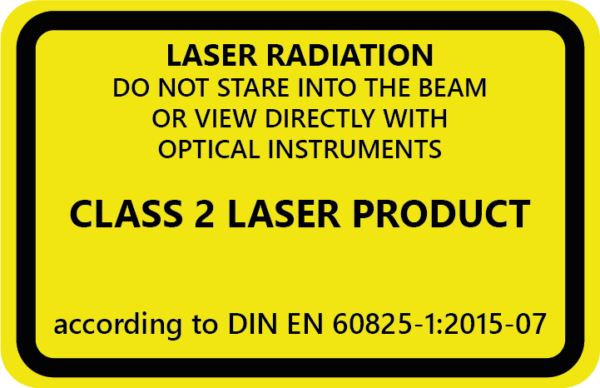

Laser Class 2

The accessible laser radiation is only in the visible spectral range (400 nm to 700 nm). It is harmless to the eye for a short exposure time (up to 0.25 s). The eye is protected by the eyelid closure reflex when looking into the laser radiation for a short time. For continuous beam lasers of class 2, the limit value of accessible radiation (GZS) is 1 mW (for C6 equals 1).

In the case of Class 2 laser equipment, there is generally no laser area requiring additional safety measures if the operation of such laser equipment allows only accidental irradiation of persons.

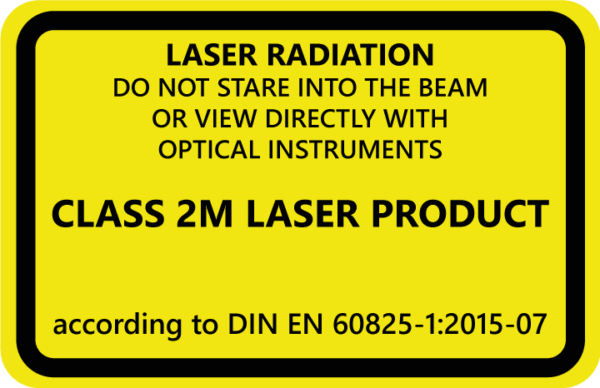

Laser Class 2M

The accessible laser radiation lies only in the visible spectral range (400 nm to 700 nm). It is harmless to the eye when irradiated for a short time (up to 0.25 s), which is protected by the eyelid closure reflex when it looks into the laser radiation at random for a short time. For class 2M continuously radiating lasers, the limit value of the accessible radiation (GZS) is 1 mW.

Class 2M laser equipment may be used without further protective measures if it is ensured that it cannot be intentionally looked into for longer than 0.25 s or repeatedly looked into the laser radiation or directly reflected laser radiation.

In addition, it must be ensured that no optically collecting instruments are used in the projection area.

Class 2M laser devices generally do not have an additional laser area to be secured if only random irradiation of persons is possible during operation of these laser devices and no optically collecting instruments are used.

Laser Class 3R

Laser class 3R devices are potentially dangerous to the eyes. The risk of eye damage is reduced by the maximum accessible radiation (GZS) limit:

- 5 times the limit value of laser class 2 in the visible wavelength range/li>

- 5 times the limit value of laser class 1 in the remaining wavelength range

For class 3R continuous beam lasers, the accessible radiation limit (GZS) is 5 mW.

Laser Class 3B

The laser class 3B is dangerous for the eyes and potentially also for the skin. Persons must not be exposed to the laser beam. Diffusely scattered laser radiation is not dangerous as long as the viewing distance of 13 cm and a viewing duration of less than 10 s are guaranteed. There is a risk of fire if the laser beam comes into contact with flammable materials.

The maximum output power is 500 mW.

When setting up and working within the working area of the laser beam, suitable protective clothing, laser goggles and gloves must be worn. The working area of the laser beam must be marked with suitable warning signs.

Laser equipment must be protected against unauthorized use. An additional visual warning lamp “Laser in operation” must be used to indicate when the laser is switched on. The warning lamp must also be clearly visible from a greater distance. The laser beam must not scatter out of the intended working area. There must be no reflective surfaces in the working area.

Before the laser is put into operation for the first time, a laser safety officer must be appointed and registered. Courses for laser safety officers are offered in Germany by TÜV, Berufsgenossenschaften or similar institutions.

Laser warning sticker class 3B

Further information on the definition of laser classes

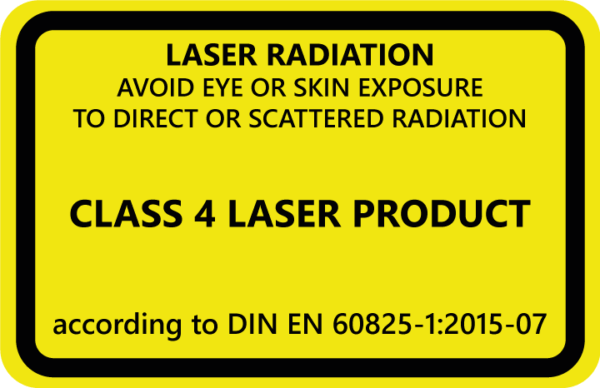

Laser Class 4

The accessible laser radiation is very dangerous for the eye and dangerous for the skin. Even diffuse scattered radiation can be dangerous. The laser radiation can cause fire and explosion hazard.

The accessible laser radiation is very dangerous for the eye and dangerous for the skin. Even diffuse scattered radiation can be dangerous. The laser radiation can cause fire and explosion hazard.

Note: Class 4 laser devices are high-power lasers whose output powers or energies exceed the accessible radiation limits (AWR) for Class 3B.

The laser radiation from Class 4 laser equipment is so intense that damage is to be expected from any type of exposure of the eyes or skin. If necessary, secure access to the room through sluices or door contacts (laser shut down) if the degree of danger so requires.

In addition, when using Class 4 laser equipment, it must always be checked whether sufficient measures have been taken against fire and explosion hazards; see also § 10 Laser radiation (previously: BGV B2) and § 16 Laser radiation (previously: BGV B2) of the accident prevention regulation Laser radiation.

Warning sign W10

The requirement for labelling is fulfilled if the warning sign W 10 "Warning of laser beam" with the corresponding additional sign according to Annex 2 of the UVV safety and health protection labelling is affixed at the workplace.

According to BGV B 2, § 8, the operator must take technical or organisational measures to ensure that irradiation above the maximum permissible level, including reflected or scattered laser radiation, is prevented. Laser radiation emitted by class 2, 3 A, 3 B or 4 laser equipment may only extend to the extent necessary for the type of application. As far as possible, the beam shall be limited at the end of the useful distance by a diffusely reflecting target surface in such a way that the risk of direct or diffuse reflection is as low as possible.

As far as possible, the unshielded laser beam should run outside the working and traffic area in an area that is as small as possible and not easily accessible, especially above or below eye level.

To protect against dangerous reflections, tools, accessories and adjustment devices used in the laser area should not have any well reflecting surfaces and those present in the laser area should not visibly carry any well reflecting objects with them. Optical components should be fixed or non-rotatable in order to keep the beam in a predetermined, very narrow solid angle (the "beam path"). Mirrors must not be brought into the beam path, which can also cause dangerous reflections.

Suitable eye protection devices which comply with the DIN EN 207 standard offer protection against direct, specularly reflected or diffusely scattered laser radiation. Despite eye protection devices, however, the direct beam must not be viewed.